FPC has a great flexibility and can be repeatedly flexed, which is very beneficial for some electronic products that need to be repeatedly bent. So what are the components of FPC?

1.Dielectric layer

The dielectric layer is commonly known as the substrate. When the FPC factory is in production, it needs to conduct electricity according to the designed line, avoiding conduction to other places and causing circuit damage.

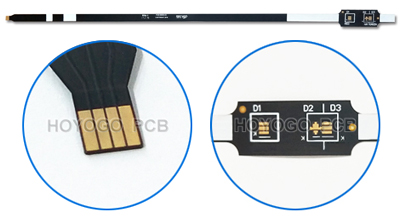

2.Silkscreen

This is a non-necessary component. Its main function is to mark the name and position frame of each part on the circuit board to facilitate post-assembly maintenance and identification.

3.Circuit and Copper Surface

One of the important component of the FPC is the circuit. And the circuit is a tool for breakover between the originals, In design, we also need to design a large copper surface as the grounding and power layer. Moreover, to ensure the higher quality of FPC, FPC factory will select the best quality materials to design the circuit.

4.Surface Treatment

The main factor that directly determines the quality and positioning of an FPC is the surface treatment process. At present, the more common surface treatment processes are immersion gold, immersion silver, gold plating, tin plating, OSP, and the like.

5.Cover Film

The FPC cover film can also be called a protective film. The main function is to protect the copper foil from exposure to air, to avoid oxidation of the copper foil; To Cover its subsequent surface treatment and it acts as a solder mask in SMT.

6.PTH (Plating Through Hole)

Nowadays, the functional requirements of electronic products are increasing, so single-layer FPC is almost no longer used. When we using a multi-layer FPC, the circuits must run through the layers in the designed order. Therefore, the FPC factory also needs to tapping in the dielectric layer at the time of production, this hole is a PTH. Two or more layers of circuits can breakover the PTH on the dielectric layer to achieve mutual conduction.

The above is the composition of the FPC. In order to ensure the final quality of the product, electronic product manufacturer should select professional and reliable FPC factory for procurement according to their own needs.