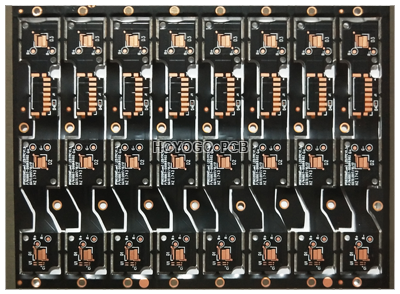

OSP is the abbreviation of “Organic Solderability

Preservative”, also known as a Preflux. It refers to an organic thin film layer

chemically formed on a clean bare copper surface.

OSP has three board categories of materials: Rosin, Active Resin and Azole. Nowadays, the most widely used by manufacturer is the Azole OSP. The Azole OSP has undergone 5 generations of improvement, namely BTA, IA, BIA, SBA and the latest APA.

OSP has many advantages. Its process is simple and reusable. OSP is low-toxic, environmentally friendly, and has good thermal shock resistance. If the PCB surface is treated with OSP, the surface will be smooth. When we print solder paste or paste SMD components, OSP can reduce the component offset and reduce the probability of SMD solder joints, making it convenient for downstream manufacturers to assemble. It allows solder and copper to be soldered directly and has good wettability. OSP processing has low energy consumption, low processing temperatures, and low cost.

Undoubtedly,OSP also has its shortcomings. It has many different types of formulas and different performances. Moreover, the protective film formed is extremely thin and is easily scratched or abrade, and the film thickness is too thick to facilitate soldering, so it must be carefully handled and operated. The OSP film after a number of high-temperature soldering processes may undergo discoloration or cracking, which may affect solderability and reliability.

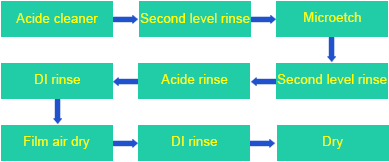

OSP process:

Among them, cleaning plays a vital role in the quality of the preservative. Poor cleaning can result in uneven thickness of the preservative. In order to ensure the high quality of the finished OSP film, it is necessary to control the concentration of the cleaning solution within the standard range by chemical laboratory analysis. On the other hand, it is recommended to check the cleaning effect as often as possible. If the effect is not up to standard, the cleaning solution should be replaced in time.

In addition, the speed of micro-etching directly affects the rate of film formation. Therefore, in order to obtain a smooth and uniform film thickness, it is important to maintain the stability of the micro-etching speed. Generally, it is appropriate to control the micro-etching thickness to 1.0-1.5 um.

All in all, because the OSP process has the advantages of no harmful substances, simple process, stable performance, and low price and so on, it is widely used.