Why are the prices of the same PCBs in different factories different, some are expensive, some are very cheap, some are moderately priced, what causes a variety of PCB price differences? This may be due to differences in materials and processes and others. The specific price differences are as follows.

1. Different PCB base material result in price diversification.

For ordinary double-panel, for example, if the board material, board thickness, copper thickness, etc. are different, each of them can cause huge price difference. In terms of solder mask, there is also a certain price difference between ordinary heat set ink and photosensitive green oil.

2. Different surface treatment process result in price diversity.

Common surface treatments: OSP, Leaded HASL, LF HASL, gold plating, immersion gold and some combined process ect. The above is arranged by price from cheap to expensive.

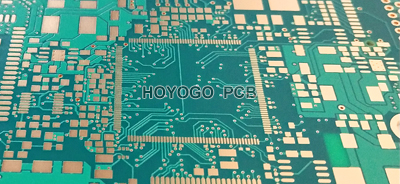

3. Different PCB have different manufacturing difficulties, resulting in price diversification

If there are 1000 holes on both PCBs, one of the PCBs has a hole diameter greater than 0.2mm, and the other PCB has a hole diameter of less than 0.2mm, they will form different drilling costs; if the two boards are the same, but the line width is different. One is greater than 4 mils, and one is less than 4 mils, which will result in different production costs; in addition, there are some designs that do not take the ordinary PCB technological process, and also need to add money, such as half-hole, blind&buried via, via in pad, button-printed carbon oil.

4. Different thickness of Copper foil result in price diversification.

Common copper foil thickness: 18um(1/2OZ), 35um(1OZ), 70um(2OZ), 105um(3OZ), 140um(4OZ), etc. The above is arranged by price from cheap to expensive.

5. Mold cost and NRE(Non-Recurring Engineering Cost)

(1)Mold cost: If it is a sample or a small batch, the general PCB board factory adopts the drilling and milling shape, and there is no additional milling edge fee.

(2)NRE: The prototype usually tested by flying probes. PCB manufacturers generally charge a NRE ranging from 100-400 RMB; the batch is to be tested by the test frame. The price of the NRE is between 1000 and 1500 RMB.

6. Order volume / delivery time

(1)The smaller the quantity, the more expensive the unite price is. Even if you only do 1PCS, the PCB factory has to do engineering materials, film, testing, etc. Every process is indispensable and will increase costs.

(2)Delivery time: The data to be handed over to the PCB factory must be complete. For example, gerber file, layer counts, base material, board thickness, surface treatment, solder mask color and some special requirements should be clearly written.

The main factors affecting PCB price differentiation are the above. And remind again: Not the smaller the quantity, the cheaper price is. So when you order a small batch of PCB, you should be psychologically prepared about the price, but usually the PCB price will not be much higher.

If you have PCB needs, you are welcome to send us the gerber file. We will quote you competitive price a.s.a.p.