The impedance control circuit of the rigid-flex board is also called the impedance strip. When the current that needs to pass through the circuit is greater than the maximum value that the circuit can withstand, it is necessary to use impedance to control the excess current, which is the principle of impedance control. Many aspects will affect the resistance value of the impedance line, do you know any aspects?

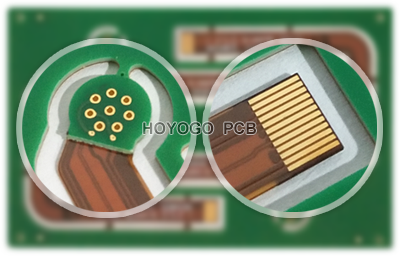

1. Different substrates lead to different impedance values

The difference of the substrate material has a great influence on the flexible board. Not only the resistance value of each material is different, but even in the case of the same material, the resistance value of each part will not be exactly the same, just as there are no two same leaves in the world. The impedance circuit on the impedance board generally uses a substrate with good material stability. If the material with poor stability is used, when the resistance value of the material changes greatly, once the required impedance value is exceeded, the impedance line cannot be used to control the circuit.

2. Line width spacing

The difference in line width and spacing between impedance lines will cause the resistance value to change. The impedance line is used as a resistor, so the width of the line is the size of the resistance value. The electric current between the circuit boards will produce a magnetic field, and the magnetic field can also produce electric current. At this time, the electric current will change, which indirectly leads to inaccurate impedance control data.

3. Tolerance of electroplating copper

The impact of this depends on the process flow. Because some processes are electroplated before etching, the impedance will not be affected during copper electroplating. However, during the manufacturing process of most flexible boards, the etching circuit has been completed during electroplating. At this time, copper will be attached to the impedance circuit, resulting in the change of the resistance value of the impedance circuit.

4. Etching tolerance

The chemical corrosion reaction of etching on the circuit will affect the thickness and width of the circuit. Etching can only be kept within one range, and there will be deviations, which are the reasons for the change of resistance value.

HOYOGO is an international, professional and reliable rigid-flex PCB Manufacturer, we have 2 production bases. Our production is strictly following high quality system of automotive products, we certified with ISO9001, ISO14001, ISO13485 and TS16949 and C-UL-S. All products strictly follow acceptance standard IPC-A-600-H and IPC-6012.