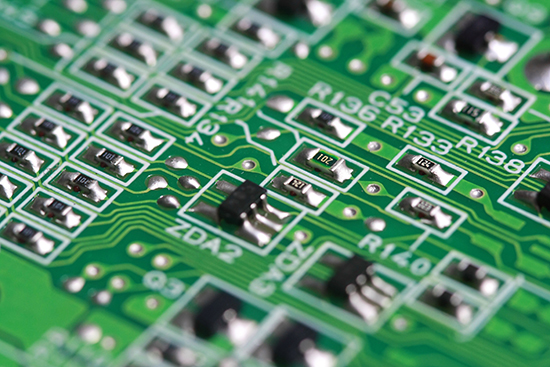

With the development of automotive intelligence, connectivity, and electrification, vehicle central control systems have evolved into the core platform of the intelligent cockpit, integrating navigation, entertainment, human-machine interaction, and vehicle information display. As the hardware foundation, automotive PCBs are responsible for high-speed signal transmission, power management, signal integrity, and module interconnection. Their reliability directly affects the vehicle’s interaction experience and system stability. As an automotive PCB manufacturer, HoYoGo focuses on the production and quality control of automotive-grade high-reliability PCBs, providing stable and reliable hardware support for central control systems.

1. Core Computing and Display Control Platform of the Central Control System

Modern vehicle central control systems typically integrate high-performance SoCs, GPUs, and display driver chips to support large high-definition displays, multi-window operation, and complex UI animation effects. To ensure the stability of the display signal chain, automotive PCBs must provide stable high-speed signal channels and precise impedance control, enabling reliable transmission of LVDS, eDP, MIPI, and other high-speed interfaces under automotive-grade conditions such as high temperatures, vibration, and EMI/EMC challenges. High-consistency PCB structures and accurate impedance control are the fundamental guarantees for stable display performance and smooth touch response in vehicle central control systems.

2. Electrical Support for Multifunctional Human-Machine Interaction (HMI)

Vehicle central control systems integrate multiple input methods, including touchscreens, rotary knobs, physical buttons, microphones and voice interaction modules, as well as proximity sensors and ambient light sensors. Through proper functional partitioning, grounding and shielding strategies, and EMC/EMI design techniques, automotive PCBs help reduce crosstalk and interference risks when multiple input signals operate simultaneously. Optimizing the routing, filtering, and protection of touch, audio, and control signals improves system response speed and operational stability, thereby enhancing the overall human-machine interaction experience.

3. Integrated Carrier of In-Vehicle Infotainment (IVI) Systems

The central control system (IVI/HU) is a key core unit of the in-vehicle infotainment system and must support audio and video playback, navigation and positioning (GNSS), in-vehicle applications, as well as wireless connectivity such as Bluetooth, Wi-Fi, and cellular networks. Automotive PCBs provide stable interconnection and power distribution for critical modules including memory, audio codecs, power management, and wireless communication. Through impedance control and EMC/EMI design, they ensure reliable multimedia data transmission over high-speed interface links.

4. Central Interface for Vehicle Status and Function Control

Through communication buses such as CAN/CAN FD, LIN, FlexRay, or automotive Ethernet, the central control system exchanges information with various vehicle control units. Automotive PCBs must provide stable interfaces and reliable signal transmission by means of proper routing and reference plane design, impedance control, and EMC/EMI measures. This ensures accurate display of vehicle status and stable control of functions such as air conditioning, seats, and lighting. The level of control over interface layout, impedance consistency, signal integrity, and anti-interference capability directly affects the stability and reliability of in-vehicle communications.

5. High Reliability and Automotive-Grade Environmental Adaptability

Automotive central control PCBs are required to operate long-term under wide temperature ranges, vibration, and complex electromagnetic (EMI/EMC) environments, and therefore must meet stringent automotive-grade reliability requirements. By selecting automotive-grade base materials, optimizing stack-up structures and copper thickness, enhancing solderability and thermal reliability processes, and implementing strict process quality consistency control, automotive PCBs ensure stable operation of central control systems throughout the vehicle’s lifecycle and reduce the risk of functional failures caused by electronic faults.

6. Hardware Foundation Supporting Intelligence and Functional Expansion

With the widespread adoption of voice assistants, online services, and intelligent scenario control, the software functions of central control systems continue to expand, placing higher demands on hardware platforms in terms of bandwidth, component integration, and scalability. Automotive PCBs can achieve greater routing density and signal transmission capability through multilayer stack-up designs and high-density interconnect (HDI) technology. By reserving expansion interfaces and modular integration space at key locations, automotive PCBs provide a solid foundation for future function upgrades and hardware expansion, thereby enhancing the platformization and long-term evolution capability of central control systems.

7. Enabling Vehicle Experience Upgrades and Brand Differentiation

The central control system is one of the most important interaction hubs in the vehicle cockpit, and its stability and smooth performance directly influence users’ perception of overall vehicle quality. Automotive-grade, high-reliability PCBs support higher-resolution displays, more complex human-machine interaction, and richer functional integration by providing controlled-impedance high-speed signal paths, stable power distribution, and robust EMI/EMC suppression. This enables automakers to create differentiated cockpit experiences and enhance overall brand competitiveness.

HoYoGo is an international, professional and reliable automotive PCB manufacturer with high-level automated and dedicated automotive PCB production lines. Automotive PCBs account for 49% of our total output. Our manufacturing processes strictly follow high-quality management systems and are certified to ISO9001, ISO14001, ISO13485, and IATF16949. All products comply rigorously with the IPC-A-600-H and IPC-6012 acceptance standards. If you have any related PCB requirements, we welcome your inquiries.