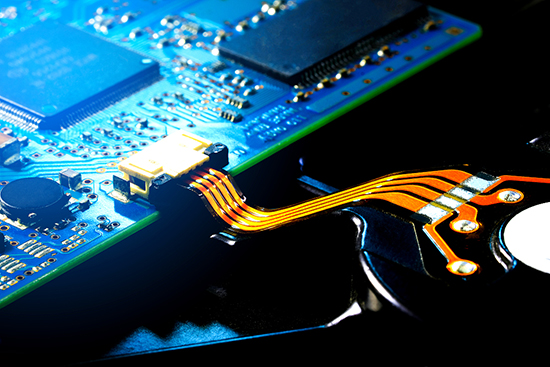

In the transformation of the photovoltaic energy storage industry toward high-density, miniaturized, and integrated designs, rigid PCBs with their large size, poor flexibility, and weak vibration resistance are increasingly unable to meet the demands of device upgrades. Flexible Printed Circuit Boards (FPCs), with their bendability, thin and lightweight structure, high wiring density, and strong reliability, have become a key technology to overcome space constraints and enhance system stability in photovoltaic energy storage equipment.

Based on the structural characteristics and functional requirements of photovoltaic energy storage devices, HOYOGO PCB’s applications mainly focus on four core components: storage battery modules, photovoltaic inverters, BMS systems, and combiner boxes. Their application methods and values are as follows:

1. Storage Battery Modules

Energy storage battery modules (e.g., lithium battery packs) are the core energy carriers of storage systems, directly determining energy storage efficiency and safety. The application of flexible PCBs in battery modules is mainly reflected in the following two aspects:

1) Cell Interconnection

Traditional battery modules use wires or copper bars to connect cells, which leads to many contact points, high resistance, and poor heat dissipation. Flexible PCBs, however, can form high-precision conductive circuits through an etching process, directly attaching to the positive and negative electrodes of the cells to achieve “solder-free” connections.

2) Embedded Temperature/Voltage Collection

Flexible PCBs can integrate components such as NTC thermistors and voltage sensing terminals, which can be directly laid on the surface of the cells to collect real-time temperature and voltage data of each cell and transmit them to the BMS system. This design eliminates the messy wiring inside the battery module, improves data acquisition accuracy, and effectively prevents risks such as cell overcharge, over-discharge, or thermal runaway.

2. Photovoltaic Inverters

As the “energy conversion core” of a photovoltaic system, the photovoltaic inverter converts the direct current (DC) generated by photovoltaic panels into alternating current (AC). It contains a large number of power devices (such as IGBTs and diodes) as well as control circuits, which place extremely high demands on wiring density and heat dissipation efficiency. Flexible PCBs offer significant advantages in this scenario:

1) Power Device Connection

In inverter systems, IGBT modules are typically designed with multiple chips connected in parallel. Rigid PCBs require complex jumper connections between the chips, which often results in uneven current distribution. Flexible PCBs, however, can be designed with curved circuits tailored to the three-dimensional structure of the IGBT module, enabling balanced connections among the chips, reducing current imbalance to below 5%, and at the same time minimizing power loss.

2) Assisted Heat Dissipation

The base materials of flexible PCBs (such as PI) have good thermal conductivity, and some high-thermal-conductivity flexible PCBs can even integrate a graphene heat-spreading layer. This layer attaches directly to the surface of power devices, transferring heat to the heat sink. Such an integrated “circuit + heat dissipation” design can reduce the operating temperature of IGBT modules by 8–12°C, significantly improving the long-term stability of the inverter, especially for high-power inverters used in centralized photovoltaic power stations.

3. Battery Management System (BMS)

The BMS is the “brain” of energy storage equipment, responsible for monitoring battery status, balancing charge and discharge, and ensuring battery safety. The stability of its signal transmission directly affects overall system reliability. The applications of flexible PCBs in BMS mainly include:

1) Integrated Signal Bus

In large-scale energy storage stations, the BMS system needs to connect dozens of battery modules. Traditional solutions rely on multiple ribbon cables to link the modules with the main control unit, which are highly susceptible to electromagnetic interference (EMI). Flexible PCBs, however, can be designed in a “bus-style” structure, integrating differential signal lines and shielding layers to improve EMI resistance by more than 30%. At the same time, they reduce the number of cable interfaces, lowering the risk of connection failures during plugging and unplugging.

2) Flexible Adapter Boards

As energy storage systems evolve toward modular designs, the BMS main control unit and battery modules are often designed to be detachable. Flexible PCBs can serve as adapter boards, enabling flexible connections between the main control unit and the modules. This allows the modules to be slightly repositioned during installation or maintenance, preventing interface damage caused by rigid connections and improving maintenance convenience.

4. Combiner Boxes

A photovoltaic combiner box is used to aggregate the direct current (DC) from multiple solar panels and transmit it to the inverter. Since it operates outdoors for long periods, it must have characteristics such as UV resistance, withstand both high and low temperatures, and corrosion resistance. The applications of flexible PCBs in this scenario are mainly reflected in:

1) Replacing Traditional Terminals

Inside the combiner box, multiple photovoltaic panel cables need to be connected. Traditional solutions use terminals and wires, which are prone to poor contact caused by the intrusion of rain or dust. Flexible PCBs, however, can directly interface with PV panel cables through waterproof connectors, while adopting a sealed design with a protection rating of up to IP67, making them well-suited for humid and dusty outdoor environments.

2) Lightweight Wiring

In large-scale photovoltaic power stations, a combiner box needs to connect more than 20 solar panels. Traditional wiring solutions can weigh as much as 5–8 kg, whereas a flexible PCB solution weighs only 1–2 kg. This significantly reduces the structural load of the combiner box and lowers the support pressure on mounting brackets during installation.

HoYoGo is an international, professional, and reliable flexible PCB factory. With strong manufacturing capabilities and meticulous quality control, we provide highly reliable and well-adapted flexible PCB products for the photovoltaic energy storage industry. Our production strictly follows international quality management systems and is certified by ISO9001, ISO14001, ISO13485, and IATF16949. All products fully comply with IPC-A-600-H and IPC-6012 acceptance standards. If you have related PCB requirements, we warmly welcome your inquiries.