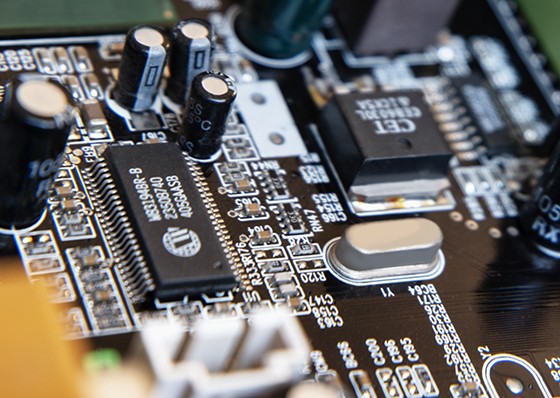

In the advancement of medicine, medical imaging technology has undoubtedly served as the "eyes" of clinical diagnosis and treatment, enabling physicians to see beyond the surface of the human body and observe internal structures and pathological changes. As a core component of medical imaging equipment, medical PCBs play a crucial role in signal transmission, data processing, and other key functions. With their high precision, high reliability, and miniaturization, medical PCBs are deeply integrated into various imaging technologies, providing a solid foundation for improved diagnostic accuracy and efficiency.

1. X-ray Imaging

X-ray imaging, a long-established and widely used medical imaging technique, forms images by passing X-rays through the human body and capturing them on a detector.

In X-ray imaging systems, medical PCBs are primarily used in X-ray generators and detector systems. In the generator, PCBs regulate high-voltage circuits to ensure stable output, precisely controlling the energy and intensity of X-rays to guarantee their quality and consistency, which is critical for reliable imaging.

In the detector system, medical PCBs connect numerous detection units, enabling efficient collection, conversion, and transmission of X-ray signals. These PCBs must exhibit high sensitivity and resolution to accurately capture faint X-ray signals, convert them into electrical signals, and transmit them to a computer for processing and image reconstruction. For example, in digital radiography (DR) systems, high-performance medical PCBs significantly enhance image clarity and detail, aiding physicians in more accurate diagnoses.

2. Computed Tomography (CT)

CT imaging captures cross-sectional views of the body, generating multi-layered images that support more comprehensive medical diagnoses.

In CT equipment, the application of medical PCB is more complex and critical. In the CT tube part, PCB controls high-voltage power supply and electron beam focusing, ensuring stable X-ray emission and precise modulation.

For the detector array, which consists of numerous sensor units, medical PCBs facilitate precise electrical connections and signal processing, enabling rapid acquisition and digitization of X-ray attenuation signals.

Additionally, CT scans generate vast amounts of data, requiring medical PCBs to handle high-speed data transmission and preprocessing, delivering information quickly and accurately to the computer's image processing system. To meet the demands of high-speed, high-resolution imaging, medical PCBs in CT systems often employ multilayer designs and high-density interconnect (HDI) technology to enhance signal transmission speed and integration.

3. Magnetic Resonance Imaging (MRI)

MRI utilizes strong magnetic fields and radiofrequency (RF) pulses to induce resonance in hydrogen nuclei within tissues, generating detailed images. Given MRI's stringent electromagnetic environment, medical PCBs must be designed with electromagnetic compatibility (EMC) in mind.

In MRI's RF transmission and reception systems, medical PCBs generate and receive RF signals. Since MRI requires precise control over RF pulse frequency, intensity, and timing, PCB design and manufacturing must achieve exceptional accuracy and stability.

To prevent electromagnetic interference (EMI) from degrading image quality, PCB layouts and wiring are meticulously designed, incorporating shielding and filtering techniques to ensure reliable operation in strong magnetic fields.

Furthermore, MRI gradient systems rely on medical PCBs to control gradient coil currents, producing spatially encoded gradient magnetic fields for precise slice selection and positional accuracy.

4. Ultrasound Imaging

Ultrasound imaging forms images by emitting sound waves into the body and receiving their echoes. In ultrasound imaging systems, medical PCBs are primarily used in ultrasound probes and signal processing circuits.

The ultrasound probe, a critical component of ultrasound imaging systems, contains PCBs that connect multiple transducer elements to transmit and receive ultrasonic waves. These PCBs must exhibit low noise and high sensitivity to accurately detect faint echo signals.

In signal processing circuits, PCBs amplify, filter, and digitize received echoes, converting them into displayable image data. As ultrasound imaging technology develops toward higher resolution and wider bandwidth, the performance requirements for medical PCBs are becoming increasingly higher, and new technologies and materials need to be continuously adopted to meet the development needs of ultrasound imaging equipment.

HoYoGo is an international, professional, and reliable medical PCB manufacturer certified to ISO13485 standards. Our production, engineering, and procurement teams consistently adhere to the highest industry certification standards. We have long-term experience and professional technology knowledge in medical PCB assembly. If you have relevant needs, you are welcome to send us an inquiry.