As an essential part of urban landscapes, fountains showcase artistic water features during the day and rely on lighting effects to create a dreamy atmosphere at night. As a professional underwater light manufacturer, HoYoGo understands that these lights must operate reliably in high-humidity, high-pressure, and even chemically treated water environments over long periods. This places stringent demands on their internal electronic structures. Therefore, underwater light PCBs must deliver excellent waterproofing, moisture resistance, corrosion resistance, and heat dissipation performance to ensure stable operation in harsh conditions.

1. Waterproofing and Heat Dissipation

Fountain lights operate continuously underwater, making waterproof encapsulation essential. Common methods include epoxy potting and silicone sealing, which completely isolate the underwater PCB’s circuitry from the surrounding water. To prevent moisture ingress that could lead to short circuits, additional protective measures such as moisture-resistant coatings or metallic anti-corrosion treatments are applied to the PCB surface.

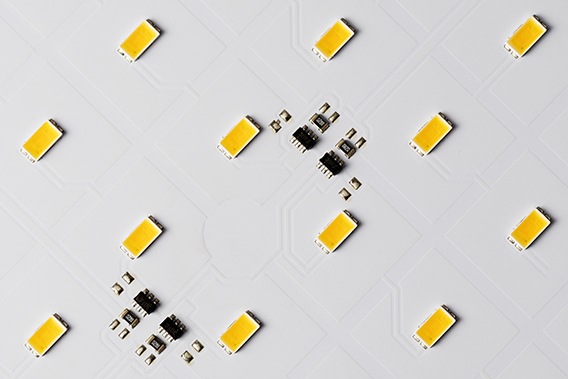

In terms of heat dissipation, fountain lights typically have relatively high power output, and insufficient thermal management can significantly shorten the lifespan of LEDs. Therefore, most underwater light PCBs use high-thermal-conductivity IMS PCB, such as aluminum-based PCB or copper-based PCBs, and transfer the heat rapidly to the lamp housing through a precisely engineered thermal pathway, allowing the surrounding water flow to carry the heat away and achieve efficient, stable cooling.

2. Corrosion Resistance and High Reliability

Fountain water may contain chlorine, impurities, and mineral salts, which can be corrosive to PCB materials. Therefore, underwater light PCBs typically use high-reliability FR-4 stiffener boards or IMS materials, supplemented with anti-oxidation surface treatments such as ENIG or electroplated gold to enhance durability and extend service life. To cope with power fluctuations and environmental interference, the design also incorporates over-current protection and lightning-protection modules to ensure safe system operation.

3. Intelligent Fountain Systems

As smart urban landscapes continue to develop, fountain lighting is increasingly integrating AI and IoT technologies. Intelligent control systems can adjust light colors and brightness in real time through wireless or wired networks, enabling dynamic interaction in musical fountain displays. The underwater light PCB plays a critical role in data transmission and signal processing, and its stability directly affects the overall coordination of the lighting system. Some high-end fountain lights also adopt multi-layer PCBs to support complex circuit integration and enhance electromagnetic compatibility.

HoYoGo is an international, professional, and reliable underwater light PCB manufacturer. Expertise shapes quality. We pursue excellence in quality control, refining every step from raw material sourcing to final delivery. Each PCB undergoes more than ten rigorous inspections to ensure exceptional waterproof performance and reliable adaptation to a wide range of complex underwater environments. If you have related requirements, we welcome your inquiries.