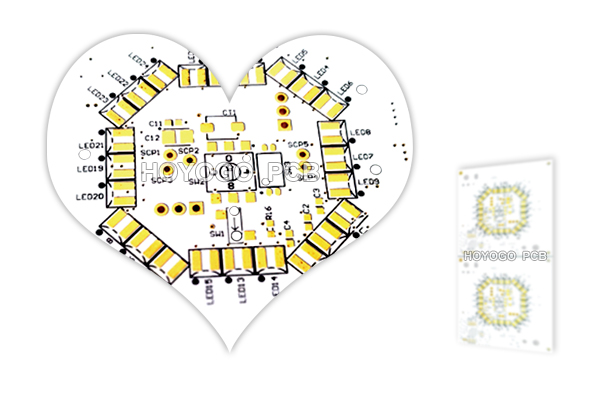

In underwater environments, marker lights are key equipment to ensure navigation safety and guide operations. As the core carrier of electronic components, the underwater light PCB largely determines the stability, reliability, and functional performance of these lights. In this crucial area, HOYOGO PCB, with more than 14 years of professional manufacturing experience and a complete ISO and UL quality system, provides strong support for underwater lighting customers worldwide.

1. Waterproof Sealing Design

The core requirement of underwater marker lights is to operate continuously under harsh conditions such as long-term immersion, water pressure changes, and water corrosion, which imposes strict demands on PCBs. For waterproof sealing, the underwater light PCB must work with the overall structure of the marker light to achieve multiple layers of protection.

Since conventional PCB substrates and solder joints are easily corroded by water, underwater light PCBs often adopt waterproof coating technology with a thickness of 50–100 μm, effectively blocking moisture penetration. Meanwhile, grooves are designed at the junction of the PCB edge and the lamp housing, paired with waterproof gaskets to achieve physical sealing and prevent water intrusion caused by pressure. This ensures stable operation of marker lights at depths of 10–50 meters.

2. Corrosion Resistance and Anti-Interference

The choice of materials and technologies for underwater light PCBs directly affects the service life of marker lights. Different water qualities, such as seawater and freshwater, contain corrosive substances like chloride ions and microorganisms. Ordinary FR-4 PCBs are prone to substrate delamination and solder joint rusting. Therefore, underwater light PCBs commonly use high-TG FR-4, polyimide, or metal substrates with stronger corrosion resistance, and apply electroless nickel immersion gold (ENIG) surface finishes to enhance corrosion resistance and electrical stability. This enables marker lights to last 5–8 years or even longer.

Additionally, the underwater environments may experience complex electromagnetic interference from ship communications and underwater power equipment. To avoid such interference from causing flickering or unstable brightness, the underwater light PCB optimizes its circuit layout, separates power and signal loops, and adds grounding copper foil and filter capacitors on key signal lines. This effectively ensures the clarity and stability of the light signals.

3. Functional Adaptation

The underwater light PCB must be custom-designed to meet the requirements of different marker-light applications.

Harbor Channel Warning Lights: These lights need high brightness and long endurance. The PCB employs a multi-channel LED driver circuit and integrates a high-efficiency DC-DC converter to keep the voltage stable at 3.3–12 V. At the same time, copper pads for heat dissipation are reserved on the PCB, working with the marker light’s metal housing to quickly release the heat generated by the LEDs, preventing high temperatures from aging the PCB substrate.

Marine Scientific Research Marker Lights: These lights require data-transmission capabilities. The PCB integrates Bluetooth or underwater acoustic communication modules and uses a miniaturized layout to combine the communication chip, antenna interface, and lighting driver circuit on a single board. This achieves a “lighting + positioning” dual function, meeting the precise guidance needs of scientific research equipment.

HoYoGo is an international, professional, and reliable underwater light PCB manufacturer. Professionalism creates quality. We are dedicated to excellence in every detail. From raw material sourcing to final delivery, each PCB undergoes more than ten rigorous inspections, ensuring outstanding waterproof performance to handle complex underwater environments with ease. If you have related needs, please feel free to send us your inquiry.