Music is not only just a combination of melodies, but also an expression of emotion. In the fast pace of modern life, the car is not only just a simple means ...

2024/04/17

Hey, have you heard that Shenzhen Library North Branch is a wonderful place that combines good looks and high technology. It seems like a magical paradise with a strong lite...

2024/04/12

The automotive engine is regarded as the core component of the automobile and undertakes the key task of driving the normal operation of the automobile. In this critical eng...

2024/04/10

On the west bank of Bijiashan Park, there is a place that will make your blood boil - Bijiashan Sports Park! This is Shenzhen's "Sports Treasure". It covering an area of about 26...

2024/04/03

Shenzhen Metro, which has entered the intelligent era, has launched a series of intelligent services supported by artificial intelligence technology to provide citizens and passe...

2024/03/28

Recently, major news media have reported that Shenzhen has a lot of “AI”! What is AI? Its full English name is Artificial Intelligence. Although it sounds a bit far away from dai...

2024/03/25

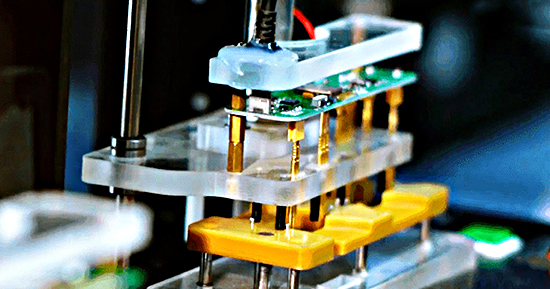

In electronic manufacturing field, PCBA E-test fixtures are key equipment to ensure the quality and reliability of circuit boards. It is like the meticulous inspector, holding a ...

2024/03/21

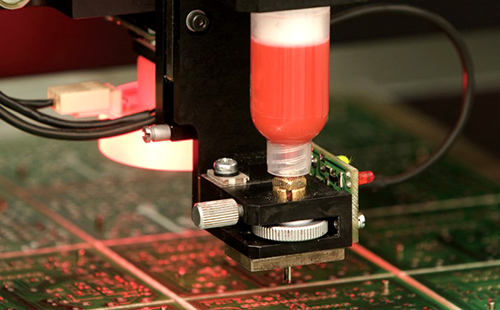

Red Glue is a polyolefin compound and an SMT material. It is different from solder paste in that red glue solidifies when heated. When the freezing point temperature reaches 150℃...

2024/03/15

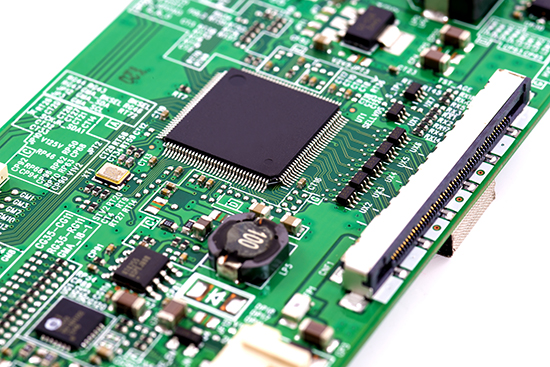

Wave soldering plays a key role in the PCB assembly process. Its main function is to effectively connect electronic components to PCB boards through soldering technology. Du...

2024/03/12

Under certain high temperature conditions, the resin melt viscosity of the prepreg is closely related to the lamination technology of the PCB board. Optimizing the matc...

2024/03/08