In the precise systems of industrial automation, industrial control PCBs serve as a crucial bridge between a device’s “perception” and “action”, with their performance directly determining the system’s operational efficiency. Whether it's ensuring stable data transmission, resisting external interference, or meeting the needs of real-time processing and high-efficiency integration, a series of key technical breakthroughs and applications are required for industrial control PCBs to play a central role in industrial automation.

1. High Reliability and Stability

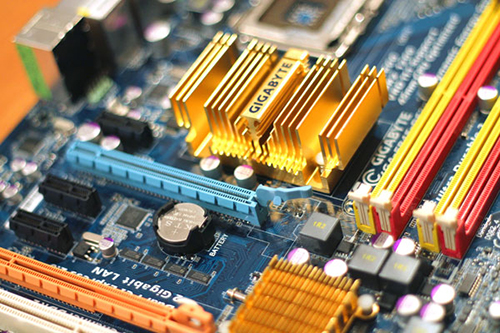

Industrial automation environments are often harsh, involving high/low temperatures, humidity, dust, vibration, and other challenging conditions. Industrial control PCBs must possess excellent environmental resistance to ensure long-term, stable operation in such complex environments. This requires the use of high-quality substrate materials, components, and packaging processes to enhance corrosion resistance, aging resistance, and vibration resistance. For example, using metal or ceramic substrates instead of standard FR-4 substrate can improve heat dissipation and mechanical strength. Additionally, employing surface-mount technology (SMT) and wave soldering ensures the soldering quality and reliability of components.

2. Anti-Interference Capability

Industrial environments are filled with electromagnetic interference (EMI) sources, such as motors, frequency converters, and relays, which generate electromagnetic radiation and electromagnetic pulses during operation. Industrial control PCBs must demonstrate excellent electromagnetic compatibility (EMC), using optimized routing design, shielding, and grounding techniques to minimize the impact of EMI on the system. For instance, adopting multi-layer PCB designs and expanding ground and power planes helps reduce crosstalk between signals. Applying conductive coatings on the PCB surface or installing shielding enclosures can prevent external EMI from affecting the system.

3. High Performance and High Integration

With the continuous development of industrial automation technology, higher requirements are being placed on the processing power and integration of industrial control PCBs. To meet the needs of real-time control and big data processing, PCBs must integrate high-performance processors, large-capacity memory, and high-speed communication interfaces. At the same time, high-density packaging technologies (e.g., BGA, CSP) and multi-layer routing techniques are employed to reduce PCB size and enhance integration. For example, in Industrial Internet of Things (IIoT) applications, industrial control PCBs must integrate wireless communication modules, edge computing chips, and other functional modules to enable intelligent device connectivity and data processing.

HoYoGo is a professional, stable and reliable PCB manufacturer with more than 14 years of experience. We strictly follow the ISO 9001 Quality Management System, ensuring rigorous inspections and control at every stage from raw material procurement to finished product shipment. By selecting premium materials such as high-Tg laminates and environmentally friendly inks, combined with advanced production equipment and refined craftsmanship, our industrial control PCBs deliver excellent electrical performance, high-temperature resistance, and corrosion resistance. Whether in harsh industrial environments or during long-term continuous operation, our products consistently deliver stable performance, ensuring reliable operation for your equipment