In the medical field, the quality of surgical lighting directly impacts the success of an operation and the safety of the patient. Bright, uniform, and stable illumination is essential for surgeons to observe the surgical area precisely and perform procedures with accuracy, minimizing risks. As a core component of surgical lighting equipment, medical PCBs play an indispensable role with their exceptional performance and highly integrated design.

1. Surgical Lighting Under Strict Standards

Surgical lighting devices must meet extremely stringent requirements. First, they must offer high brightness and excellent color rendering to ensure surgeons can clearly distinguish tissue colors and fine structures. Second, the light must be distributed evenly to avoid shadows that could obstruct the surgical field. Furthermore, the lighting equipment must offer light stability, ensuring consistent illumination throughout prolonged surgical procedures. Given the unique requirement of medical environments, the equipment must also meet strict hygiene and safety standards and able to withstand regular disinfection and sterilization processes.

2. Core Advantages of Medical PCB

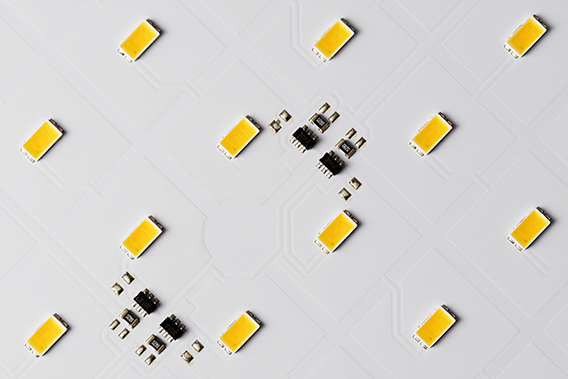

Medical PCBs are specially designed to meet the needs of surgical lighting, featuring several unique characteristics. By utilizing high-quality insulation materials and precision circuit layouts, they effectively minimize electromagnetic interference and ensure the stable performance of the lighting system. In terms of materials, medical PCBs are typically made with medical-grade substrates that offer excellent chemical stability, enabling them to resist corrosion from common disinfectants and thereby extend the equipment’s service life. In addition, their superior electrical performance supports complex circuit designs, allowing precise control of surgical lighting systems.

3. Precision Control of Light Sources

Medical PCBs are applied in several key areas of surgical lighting systems. In terms of light source control, they integrate driver chips and control circuits to precisely adjust LED brightness, color temperature, and flicker frequency. Surgeons can flexibly adjust lighting parameters via the user interfaces to accommodate different surgical requirements. For example, ophthalmic surgeries require high-brightness, cool-color light to highlight the fine structure of the eye tissue, whereas orthopedic procedures place greater emphasis on uniform illumination to avoid shadows that may interfere with the observation and manipulation of bones. The intelligent control functions of medical PCBs respond swiftly to these varying needs, providing an ideal lighting environment for surgery.

4. Robust Support for Thermal Management

Thermal management is a major challenge in surgical lighting. As prolonged high-intensity illumination generate significant heat. Without timely and efficient thermal management, this heat can impair the performance and lifespan of the light source and even pose safety risks during surgery. Medical PCBs address this through specialized structures and materials, such as large copper areas and thermal vias, which rapidly conduct heat away from the light source. Some medical PCBs are also integrated with auxiliary cooling components such as heat sinks or fans to further enhance heat dissipation efficiency. This ensures that the light source operates stably at an optimal temperature, extends the lifespan of the equipment, and guarantees the reliability of surgical lighting.

5. Flexible Adaptation of Dimming Technology

Dimming is another vital function enabled by medical PCBs in surgical lighting. By employing PWM (Pulse Width Modulation) dimming technology, medical PCBs enable smooth and continuous adjustment of LED brightness, offering virtually infinite levels from the dimmest to the brightest to meet the varying illumination requirements at different stages of surgery. During the preoperative preparation phase, the lighting can be dimmed to create a comfortable environment. During the surgical procedure itself, the brightness is adjusted to an optimal level to ensure clear visibility. Additionally, the dimming function helps prevent discomfort caused by sudden changes in light intensity, enhancing both the comfort and safety of surgical operations.

6. Deep Integration with Smart Lighting

Medical PCBs play a central role in advancing the intelligence and integration of surgical lighting systems. As medical technology continues to advance, surgical lighting systems is evolving toward smarter solutions. Serving as the "brain" of the device, medical PCBs integrate sensors, communication modules, and other functional components. With built-in ambient light sensors, surgical lighting devices can automatically detect surrounding light levels and adjust their brightness accordingly. Additionally, medical PCBs support wireless communication, enabling connection with central operating room control systems. Surgeons can conveniently adjust lighting parameters via tablets or smart terminals, improving operational efficiency and user experience.

With superior performance and a high level of integration, medical PCBs play a vital role in surgical lighting. From light source control and thermal management to dimming and smart functionality, they provide comprehensive technical support to enhance the quality and safety of surgical lighting. As medical technology continues to advance, medical PCBs will keep evolving and improving, bringing more innovative solutions to surgical lighting and providing more solid protection for patient health and surgical success.

HoYoGo is a professional medical PCB manufacturer with rich experience and professional technology in medical PCB production. We specialize in producing high-performance, high-quality, and high-difficulty PCB, and can guarantee the quality and reliability of each product delivered to customers. If you have related needs, feel free to contact us!