In the process of and PCB manufacturing, ensuring their electrical performance and quality is crucial. PCB test fixtures and flying probe testing are two common methods for electrical performance inspection. So, what are the differences between them?

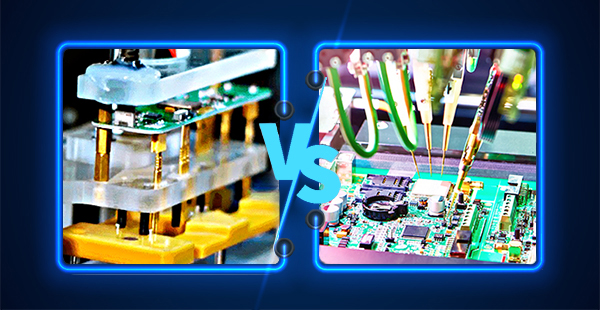

PCB Test Fixture

A PCB test fixture is a specialized device used to test the electrical performance of PCBs. By simulating the actual working environment of the PCB, it ensures that each board functions properly before being put into use.

The test fixture uses probes to make contact with test points on the PCB, transmitting signals to a control unit. The control unit executes pre-set test programs to detect issues such as short circuits, open circuits, etc., and records the test results.

PCB test fixtures are suitable for large-scale production. They use a test bed with multiple pins to directly contact multiple points on the PCB. This method is highly efficient, but the initial setup and debugging are relatively complex.

Advantages of PCB Test Fixtures: Efficient and fast testing of PCB quality, reduced human error, and assurance that every circuit board meets standards.

Flying Probe Testing

Flying Probe Test (FPT) is used to inspect the electrical performance and manufacturing defects of PCBs. Unlike bed-of-nails testing, flying probe testing does not require dedicated test fixtures. Instead, it uses multiple independently movable probes to quickly contact test points, enabling automated inspection.

Flying probe testing uses software to control probe paths, allowing quick adaptation to design changes. It is suitable for prototypes and small-batch production. It can test for open circuits, short circuits, resistance, capacitance, inductance, diode polarity, etc. Some equipment can even verify component values (e.g., resistor resistance, capacitor capacitance).

The probes in flying probe testing can precisely contact tiny pads or high-density PCB layouts (e.g., BGA packages, HDI boards).

SHENZHEN HOYOGO ELECTRONIC TECHNOLOGY CO., LTD. is a professional and reliable PCB manufacturer, offering customers one-stop services ranging from upstream electronic component procurement to PCB production, SMT patching, PCBA testing, and finished product assembly. If you have related needs, please feel free to send us an inquiry.