As smart cockpits continue to evolve, zero-gravity seats have become a key configuration for improving driving comfort. Acting as the electronic control core, automotive PCBs including flexible PCBs, rigid PCBs, and rigid-flex PCBs play an irreplaceable role in spatial adaptation, signal transmission, and functional reliability. This article dives into how these three types of PCBs are typically applied in zero-gravity seats and their key advantages.

1. Flexible PCBs: Perfect Fit for the Intricate Space of Zero-Gravity Seats

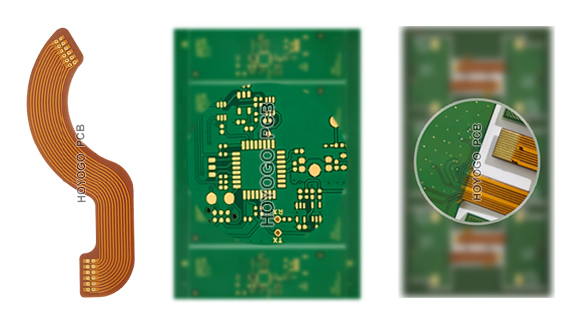

In more specific terms, automotive PCBs come in many forms, among which flexible PCBs are particularly widely used in zero-gravity seats. Made from flexible materials, these PCBs can bend freely and fit precisely within the seat’s complex internal structures. In the face of tight and irregular spaces, they enable efficient circuit routing and save space, while reliably connecting adjustment motors, sensors, heating, and ventilation modules.

2. Rigid PCBs: High Strength and Stable Signal Control

As one of the typical automotive PCB solutions, rigid PCBs are usually made with automotive-grade high-TG FR4 and other materials, giving them high mechanical strength and excellent heat resistance. In zero-gravity seats, this type of automotive PCB acts as the “main control brain,” providing stable electrical connections and data processing for core functions such as motor adjustment, memory storage, and seat safety control. With outstanding heat and vibration resistance, rigid PCBs can maintain precise signal transmission and stable operation under high temperatures and prolonged vibration, ensuring a consistently reliable and comfortable user experience.

3. Rigid-Flex PCBs: Key to Zero-Gravity Seat Lighting Systems

As an important type of automotive PCB used in zero-gravity seat lighting systems, rigid-flex PCBs combine the properties of both flexible and rigid materials, enabling stable wiring in complex shapes. They are widely applied to seat ambient lighting, USB ports, and decorative light strips, enhancing installation flexibility while improving overall aesthetics and functional integration.

HoYoGo is a professional, reliable automotive PCB manufacturer, providing one-stop services from upstream electronic component sourcing to PCB production and processing, SMT assembly, PCBA testing, final product assembly. All products strictly comply with IPC-A-600-H and IPC-6012 standards, with rigorous inspections at every stage to ensure peace of mind for customers.