Shenzhen HoYoGo Company has its own SMT factory. We can provide SMT processing services for the Smallest package 0201 components, and supports various processing forms such as accepts customers' materials for processing and OEM. Next, we will introduce to you what inspections are required before SMT processing?

First, SMT component inspection

The main inspection items of components include: Solderability, pin coplanarity and usability. Sampling inspection should be done by the inspection department.

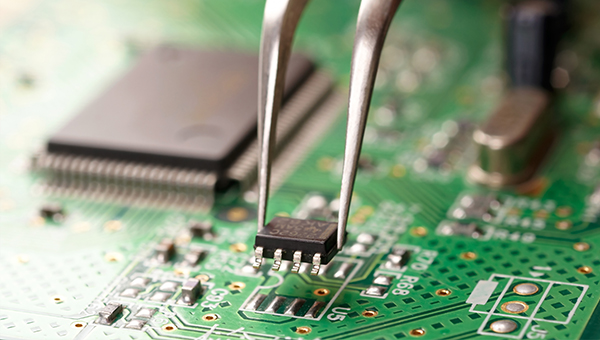

In order to test the solderability of the components, stainless steel tweezers can hold the component body and immerse it in a tin pot at 235±5℃ or 230±5℃, and take it out at 2±0.2s or 3±0.5s. Check the soldering end of the solder under a 20x microscope, and it is required that more than 90% of the soldering end of the component is soldered.

The SMT processing workshop can do the following visual inspections:

1. Visually or with a magnifying glass, check whether the solder ends or pin surfaces of the components are oxidized or have no contaminants.

2. The nominal value, specification, model, accuracy, and external dimensions of the components should be consistent with the product process requirements.

3. The pins of SOT and SOIC cannot be deformed. For multi-lead QFP devices with a lead pitch of less than 0.65mm, the pin coplanarity should be less than 0.1mm (which can be optically detected by the placement machine).

SMT processing are required cleaning products and components after cleaning tag does not fall off, and shall not affect the component performance and reliability. Visual inspection is required after cleaning.

Second, PCB inspection

1. The PCB pad pattern and size, solder mask, silk screen, and via hole settings should meet the design requirements of smt.

2. The external dimensions of the PCB should be consistent, and the external dimensions, positioning holes, and reference marks of the PCB should meet the requirements of the production line equipment.

3. PCB allowable warpage size:

1)Upward/convex surface: maximum 0.2mm/5Omm, maximum length 0.5mm/the length direction of the whole PCB.

2)Downward/concave surface: maximum 0.2mm/5Omm, maximum length 1.5mm/the length direction of the whole PCB.

4. Check whether the PCB is contaminated or damp.

Third, SMT processing precautions

1. SMT technicians need to wear an electrostatic ring that can be used normally, and check that the electronic components of each order are free of errors/mixing, damage, deformation, scratches, etc. before plug-in.

2. The plug-in board of the circuit board needs to be prepared in advance by the SMT technicians, and pay attention to the correct polarity of the capacitor.

3. After the smt printing operation is completed, it is necessary to check for defective products such as no missing insertion, reverse insertion, misalignment, etc., and the good tin finished products are flowed into the next process.

4. Please wear an electrostatic ring before SMT processing and assembly operations. The metal sheet should be close to the skin of your wrist and be well grounded. Work with your hands alternately.

5. For metal components such as USB/IF socket/shielding cover/tuner/network port terminal, you must wear finger cots when plugging in.

6. The position and direction of the inserted components must be correct, the components should be flat against the board surface, and the elevated components must be inserted at the K foot position.

7. If materials are found to be inconsistent with the specifications on the SOP and BOM, they must report to the shift/group leader in time.

8. The materials should be handled with care. Please do not let the PCB that has passed the SMT previous processes fall off, causing damage to the components. The crystal oscillator cannot be used after it is dropped.

9. Please tidy up and keep the work surface clean before going to and from work.

Please strictly abide by the operating rules of the work area. It is strictly forbidden to place products in the first inspection area, inspection waiting area, defective area, maintenance area, and low material area without authorization. In addition, the unfinished process should be indicated in the handover.