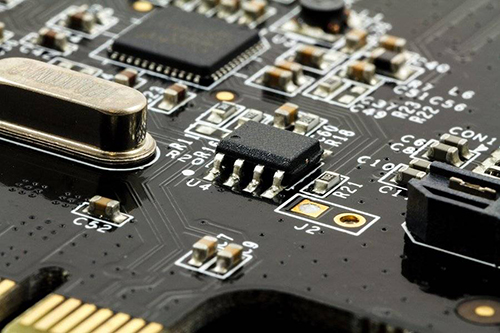

SMT is a mounting technology that does not require drilling insertion holes on the PCBA board, but directly attaches or solders surface mount components to the component positions specified on the surface of the PCBA board. So what are the advantages of SMT processing?

1. Miniaturization

SMT processing has the characteristics of high assembly density, small size and light weight.The volume and weight of SMT components are only about 1/10 of those of traditional plug-in components. Generally, electronic products are reduced by 40%~60% in volume and 60%~80% in weight after using SMT. The distance between the adjacent electrodes of the SMT components is much smaller than the lead spacing of the traditional DIP integrated circuit, and the current pin spacing has reached 0.3mm.

2. Electrical Properties

Surface mount components reduce parasitic lead and conductor inductance while improving the characteristics of capacitors, resistors and other components. It can make the transmission delay small, the signal transmission speed is accelerated, and the radio frequency interference is eliminated at the same time, so that the high-frequency characteristics of the circuit are better, the working speed is faster, the noise is obviously reduced, and the electromagnetic interference is also reduced.

3. Automation

The standardization, serialization and welding conditions of the chip components used in SMT processing are consistent, the automation degree of surface mounting is high, and the production efficiency has been greatly improved.

4. Cost Reduction

The volume of SMT components is generally reduced, resulting in reduced packaging material consumption. In the SMT processing, the components do not need to be pre-shaped and cut, and the PCBA board does not need to be punched, saving manpower and material resources, thereby generally reducing the production cost.

5. Quality improvement

SMT placement technology can ensure that the solder joint defect rate of electronic products or components is low.Therefore, electronic components or electronic products processed with SMT have strong vibration resistance, high reliability, and can also reduce electromagnetic and radio frequency interference.