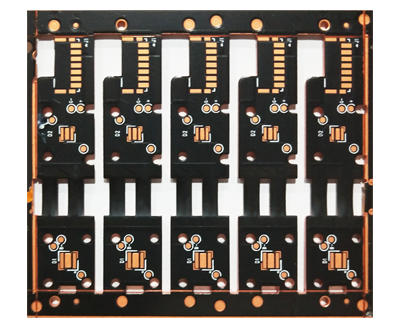

The copper base PCB is mainly based on copper, and its composition structure are the same as that of the aluminum PCB, which are the copper base layer, the insulating layer and the circuit layer.

1. The circuit layer of the copper base PCB is required to have a large current carrying capacity, so thicker copper foil should be used.

2. The insulating layer is the core technology of the copper base PCB. The composition is composed of aluminum oxide and silicon powder and epoxy resin filled polymer. It has low thermal resistance, excellent viscoelasticity, thermal aging resistance, and can withstand mechanical and thermal stress.

3. The metal base layer is the support member of the copper base PCB, which requires high thermal conductivity and is suitable for conventional machining such as drilling, punching and cutting.

4. Copper base PCB can be machined into metallized holes, but aluminum PCB cannot. The network of metallized holes must be the same network, so that the signal has good grounding performance. Secondly, copper itself has weldability, which makes the final installation of the designed structural parts optional welding.

5. The copper base PCB can be etched with fine patterns and processed into a convex shape. The components can be directly attached to the convex to achieve excellent grounding and heat dissipation effects.

6. Due to the difference in elastic modulus between copper and aluminum, the corresponding warping degree and expansion and contraction of copper base PCB are smaller than those of aluminum PCB, and the overall performance will be more stable.

Due to the thick copper base, the minimum drilling tool diameter must be 0.4mm, and the line width and spacing can be determined according to the thickness of the copper foil on the copper base PCB. For example, the thicker the copper foil, the wider the minimum line width and the larger the minimum spacing. In addition, copper substrates are usually used for products with high thermal conductivity requirements, such as high-frequency circuits, high-power products, and precision communication equipment.

HoYoGo is an international, professional and reliable PCB manufacturer, we have our own factory, advanced machines and excellent and stable quality system. One-stop PCB product supply, support various complex processes, and also can provide you with preferential metal material prices.