As medical devices continue to evolve toward higher precision, minimally invasive designs, and intelligent functionality, lighting systems have progressed beyond basic illumination to become a critical factor influencing diagnostic accuracy, operational safety, and user comfort. With advantages such as high brightness, low power consumption, and long service life, LEDs are widely used across various medical devices. As the core carrier of the light source, LED PCBs provide electrical interconnections and thermal management, directly influencing light output stability and long term reliability.

As an LED PCB manufacturer, HoYoGo offers precision manufacturing and strict quality control tailored for medical lighting applications. We provide highly reliable and consistent LED PCB manufacturing support to help medical devices achieve stable and dependable lighting performance.

1. Special Lighting Requirements for Medical Devices

Medical applications place extremely strict requirements on lighting systems, including stable brightness output, accurate color rendering, low flicker, and a high level of operational safety. In scenarios such as surgical lights, examination lamps, and endoscope illumination, lighting quality directly affects a physician’s visual clarity and diagnostic accuracy. To support long periods of continuous operation, LED PCBs for medical lighting must be properly matched with stable driver systems. By using high-thermal-conductivity materials and low-thermal-resistance PCB structures, heat dissipation efficiency can be improved, helping to reduce lumen depreciation and color temperature drift, thereby ensuring uniform light output, low flicker performance, and long-term lighting stability.

2. The Role of LED PCBs in Light Source Stability

Medical lighting typically requires uniform and well-controlled light output. By optimizing conductive paths and routing structures, such as reducing voltage drop and supporting current balancing, LED PCBs help maintain consistent operating conditions across multiple LEDs, reducing the risk of localized over-bright or dark areas. At the same time, reliable pad design and robust interconnection structures improve assembly consistency and long-term reliability, meeting the stringent lighting precision requirements of medical devices.

3. Thermal Management and Lumen Depreciation Control

Thermal management is one of the key challenges in LED lighting systems, particularly in enclosed or miniaturized medical devices. LED PCBs commonly use high-thermal-conductivity materials and low-thermal-resistance structures, such as metal-core substrates or thermal vias to improve heat dissipation efficiency, effectively transferring operating heat away from the LEDs and reducing junction temperature. Enhanced thermal management helps extend LED service life and mitigate the risks of lumen depreciation and color temperature drift, thereby improving lighting consistency and long-term reliability in medical device applications.

4. Support for Color Rendering and Color Temperature Stability

Accurate color reproduction is critical during medical examinations and surgical procedures. High color rendering index (CRI) LEDs have become the mainstream choice for medical lighting. The thermal management capability and electrical interconnection reliability of LED PCBs influence LED operating temperature and output stability, thereby affecting color temperature consistency and long term performance. Through low thermal resistance structures and consistent manufacturing control, LED PCBs help reduce the risk of color temperature drift, enabling physicians to achieve a more consistent and reliable visual experience across different usage conditions and time periods.

5. Safety and Electrical Reliability Assurance

Medical devices impose extremely high requirements on electrical safety. LED PCBs for medical lighting typically need to meet safety requirements such as insulation, creepage and clearance distances, and dielectric withstand voltage. They should also support the implementation of customer-specific protection functions, such as overcurrent and over-temperature protection by reserving interfaces and layout space, thereby reducing safety risks under abnormal operating conditions. This helps reduce safety risks under abnormal operating conditions. In addition, the use of reliable material systems and controlled soldering processes helps reduce failure rates during long term operation, enhancing overall system safety and stability.

6. Miniaturization and Structural Compatibility

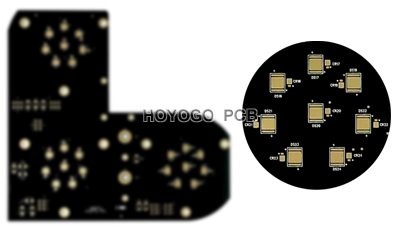

As medical devices continue to evolve toward portability and compact designs, the size of lighting modules is steadily decreasing. LED PCBs for medical lighting need to achieve high density routing and reliable interconnections within limited space, while maintaining good compatibility with power and control modules, as well as ensuring effective thermal performance and long term reliability. Through options such as irregular PCB shapes, thin PCBs, or multilayer structures, LED PCBs can be more flexibly adapted to the structural designs and installation requirements of various medical devices.

7. Typical Application Scenarios

LED PCBs are widely used in applications such as surgical shadowless lights, examination lights, endoscope illumination modules, dental treatment lights, medical headlamps, and backlighting systems for patient monitoring equipment. In these applications, LED PCBs play a key role in supporting light output stability, consistency, and long term reliability through reliable electrical interconnections and effective thermal management, thereby influencing overall device stability and service life.

8. Advancing Medical Lighting Toward Higher Quality and Reliability

LED PCBs are a key component of medical device lighting systems. Through low thermal resistance structures, reliable electrical interconnections, and consistent manufacturing and quality control, LED PCBs help enhance light output stability and long term reliability. This provides a more robust hardware foundation for medical lighting applications and supports the continued advancement of medical device lighting toward higher quality and reliability.

HoYoGo is an international, professional, and reliable LED PCB manufacturer with its own production facilities. With extensive experience, strong manufacturing capacity, and well-established resources, we are able to provide one-stop services ranging from small to large batch production. If you have any related requirements, please feel free to contact us.