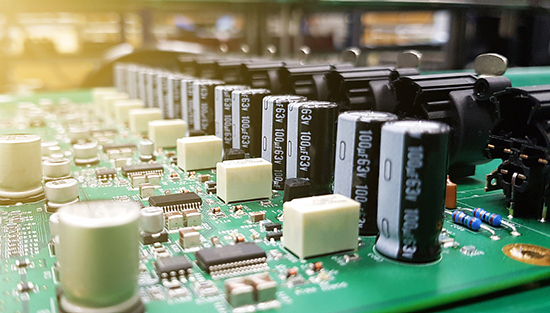

With the continuous growth in rehabilitation healthcare demand, rehabilitation training equipment is evolving from mechanically driven assistive devices into medical electronic systems that integrate sensing, performance evaluation, and intelligent control. In this process, medical PCBs serve as a critical hardware foundation, supporting core functions such as sensor signal acquisition, motion control execution, power management, and data processing. They also provide the implementation foundation for safety-related designs, including EMC/ESD protection, electrical isolation, and overcurrent and overvoltage protection, thereby supporting stable device operation and precise measurement and control performance.

As a medical PCB manufacturer, HoYoGo provides high-reliability and high-precision PCB manufacturing services for medical electronic applications, supported by full-process quality control. This enable stable and traceable hardware support for rehabilitation training equipment, while meeting safety-related design and protection requirements.

1. Foundation for Accurate Acquisition of Physiological and Motion Signals

Rehabilitation training equipment typically needs to acquire a wide range of physiological and motion parameters, including electromyography (EMG), joint angle, force/pressure, speed, and heart rate. Signal acquisition and processing circuits are commonly implemented on medical PCBs, incorporating high-precision analog front ends (AFE), low-noise amplification, and stable power and reference designs to establish reliable signal chains for various sensors. Combined with proper functional partitioning, routing, and grounding strategies, these designs effectively suppress power noise and electromagnetic interference, minimize noise and artifacts in weak signals such as EMG, and enhance the accuracy, stability, and repeatability of training data during long-term operation.

2. Core Hardware Platform for Motion Control and Execution

In electric or semi-electric rehabilitation training equipment, motion control and drive circuits are typically implemented on medical PCBs to perform key functions such as motor driving, torque and speed control, and motion trajectory control. Through high-reliability power circuitry and real-time closed-loop control, integrating feedback signals from encoders and torque or force sensors, the system can adjust training intensity and movement rhythm based on predefined training programs or real-time operating conditions. In addition, the control architecture supports safety-related strategies such as overload protection, output limiting, and abnormal state suppression, thereby reducing operational risk and enhancing overall system stability.

3. Closed-Loop Feedback and Personalized Training Support

Control systems implemented on medical PCBs can establish a closed-loop architecture of “sensing, analysis, and control.” By continuously acquiring real-time motion feedback and relevant physiological signals, and evaluating training status through algorithmic processing, the system dynamically adjusts training parameters to support personalized training programs and adaptive training strategies. This closed-loop mechanism helps enhance training precision and controllability, reduce variability caused by manual intervention, and improve consistency and repeatability throughout the training process.

4. Data Processing and Evaluation Foundation

Training evaluation and process management rely on the continuous and stable accumulation of data. Local processing units implemented on medical PCBs can perform essential data preprocessing, filtering, and feature extraction, and transmit data to host systems or rehabilitation management platforms through communication interfaces. A stable and reliable PCB architecture helps improve long-term data consistency and overall data quality, providing data support for training evaluation, trend analysis, and optimization of training parameters.

5. Safety Protection and Fault Detection Mechanisms

Rehabilitation training equipment comes into direct contact with the human body, placing higher requirements on electrical safety and system reliability. Safety control and protection circuits implemented on medical PCBs can integrate overcurrent, overvoltage, and overtemperature monitoring, as well as emergency stop response paths. Under abnormal operating conditions, the system can quickly disable drive outputs or switch to a controlled state, thereby reducing risk and minimizing potential hazards. In addition, status monitoring circuits enable online self-diagnostics and fault indication or localization for critical modules, improving system controllability and maintenance efficiency.

6. Stable Operation Across Multiple Application Scenarios

Rehabilitation training equipment is widely used in hospitals, rehabilitation centers, and home-care environments, placing higher demands on long-term stability and durability. Through the selection of material systems suitable for long-term operation, along with structural and electrical designs for vibration resistance and electromagnetic interference mitigation, medical PCBs support stable device operation under frequent use and complex electromagnetic environments, thereby reducing maintenance requirements and improving overall operational reliability.

7. Communication and System Integration Capabilities

Control systems implemented on medical PCBs can integrate wired or wireless communication interfaces to support data exchange with host systems, rehabilitation evaluation systems, or healthcare information platforms. Through stable and reliable interface and communication design, a solid foundation is provided for the transmission and centralized management of training data, enabling application scenarios such as remote rehabilitation guidance and rehabilitation progress tracking.

8. Advancing Rehabilitation Training Toward Intelligent and Precision-Oriented Development

Medical PCBs serve not only as a critical hardware foundation for rehabilitation training equipment, but also as key enablers of precise control and training evaluation. Supported by stable signal acquisition paths, reliable control and actuation circuits, and safety-related design considerations, device systems can maintain long-term operational consistency while providing a robust hardware foundation for functional upgrades and iterative optimization. As a result, rehabilitation training is continuously advanced toward more intelligent and precision-oriented development.

HoYoGo is an international, professional, and reliable medical PCB manufacturer, certified to ISO 9001, ISO 14001, and ISO 13485 management systems. We offer advanced multilayer PCB manufacturing capabilities: rigid PCBs up to 100 layers; HDI PCBs up to 32 layers; flexible PCBs up to 12 layers; and rigid-flex PCBs up to 32 layers. We manufacture PCBs and provide assembly services based on customer-supplied Gerber files, BOMs, and process requirements. If you are looking for a trustworthy medical PCB partner, please feel free to contact us or send an RFQ, we will be happy to support you.