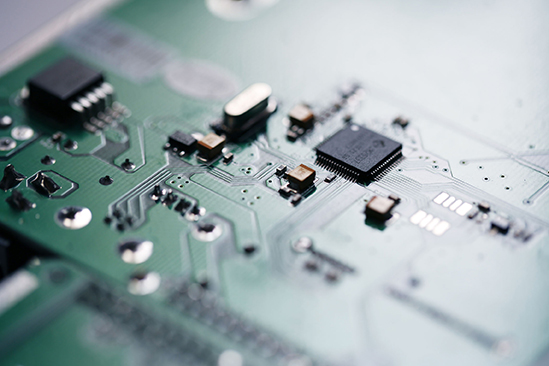

An automotive processor PCB refers to a printed circuit board used in vehicle electronic control systems to mount and interconnect processors such as MCUs and SoCs, along with the supporting power supply, memory, and communication interface circuits. These processors are typically integrated into ECUs, domain controllers, or cockpit/ADAS computing units, where they perform computing and control tasks and enable system-level coordination. As a critical hardware platform, automotive processor PCBs support component interconnection and signal transmission, forming an essential foundation for vehicle electronics and intelligent automotive functions.

As a professional PCB manufacturer, HoYoGo has accumulated extensive experience in material selection, process consistency control, and reliability management for automotive applications. We provide stable and reliable PCB manufacturing support for processor-related PCBs, helping ensure safe long-term operation and continuous system upgrades in automotive electronic systems.

1. Core Functions of Automotive Processor PCBs

As automotive electronic systems become increasingly complex, functions such as driver assistance, autonomous driving, and in-vehicle infotainment rely more heavily on high-performance processors. As a key hardware foundation of processor-based systems, automotive processor PCBs mainly serve the following functions:

1) Processor Integration and High-Speed Interconnection: Automotive processor PCBs are used to mount core devices such as MCUs and SoCs, and enable stable interconnection and high-speed communication with vehicle electronic systems through high-density routing and connectors.

2) Signal Transmission and Stable System Operation: After signals from sensors and control modules enter the control unit, the PCB handles on-board signal transmission and distribution, ensuring signal integrity and providing a reliable basis for processor decision-making and control.

3) Power Management and Reliable Power Supply: Automotive processor PCBs typically integrate voltage regulation, filtering, and protection circuits to deliver stable power to processors and critical components, enhancing overall system reliability and immunity to interference.

4) Memory and Communication Connectivity: The PCB connects memory devices and automotive communication modules, supporting data storage, internal system data exchange, and communication with external networks or devices.

2. Key Technical Characteristics of Automotive Processor PCBs

As a critical hardware platform for automotive processor systems, automotive processor PCBs must meet stringent requirements for reliability, performance, and consistency in vehicle applications. Key technical characteristics include:

1) High Performance and High Stability

Automotive applications typically operate under harsh conditions such as temperature cycling, mechanical vibration, and electromagnetic interference, requiring processor PCBs to maintain stable performance over long-term operation. So, material selection, process consistency control, and anti-interference/EMC design, such as proper grounding and shielding strategies are essential to ensuring overall system stability.

2) High-Frequency and High-Speed Signal Transmission Capability

With the advancement of ADAS and intelligent cockpit systems, processors must required to handle large volumes of high-speed data generated by cameras, radar, and other sensors, placing higher demands on signal integrity and latency. Automotive processor PCBs are designed with impedance control, differential routing, and optimized layer stack-ups to reduce signal loss and crosstalk, ensuring stable and reliable high-speed signal transmission.

3) High-Power Handling and Thermal Management Design

Automotive processors and their power supply circuits typically operate at relatively high power levels, placing increased demands on power management and thermal performance. Automotive processor PCBs are designed to support high-current power delivery while carefully considering heat conduction and dissipation paths. Through the use of thermal vias, enhanced copper planes, and integration with heat dissipation structures, heat generated during operation can be efficiently transferred away, preventing overheating and ensuring stable system performance.

4) Electromagnetic Compatibility (EMC) Design

In complex automotive electronic environments, electromagnetic interference (EMI) is a critical concern. Automotive processor PCBs require systematic EMC design measures to suppress external interference while minimizing self-generated emissions. Optimized component placement, continuous reference plane design, shielding structures, and optimized signal return paths help improve immunity to interference and enhance overall system stability.

5) Multilayer PCB Design

To integrate power delivery, signal processing, and communication interfaces within limited space, automotive processor PCBs typically adopt multilayer or high-layer-count PCB structures (such as 4-layer, 6-layer, or higher). Multilayer designs enable effective signal isolation, reliable electrical interconnection, and improved thermal management, providing a solid foundation for stable system operation.

6) Stringent Reliability and Safe Operation Requirements

Automotive processor PCBs must meet strict requirements for reliability and safe operation in vehicle applications, supporting stable processor performance under extreme operating conditions and reducing the risk of electronic failures affecting overall vehicle system operation. As a result, PCBs typically undergo systematic reliability testing and validation to ensure stable and consistent performance under harsh conditions such as high and low temperatures, humidity, and vibration.

7) Long Lifecycle and Design Continuity

Automotive products generally have long lifecycles, requiring processors and their PCBs to support long-term stable operation and continuous supply. During the design phase, compatibility with future system upgrades and product iterations must be carefully considered to ensure that the PCB solution remains reliable throughout the entire lifecycle and can adapt to the ongoing evolution of automotive technologies.

HoYoGo is an international, professional, and reliable PCB manufacturer. We provide one-stop services ranging from upstream electronic component sourcing to PCB manufacturing, SMT assembly, PCBA testing, and final product assembly. If you have related requirements, please feel free to contact us for a quotation.