The month of November is on the verge of bidding farewell to the season of autumn. The warmth remains unabated despite the arrival of winter. The promised birthday party was fill...

2023/12/15

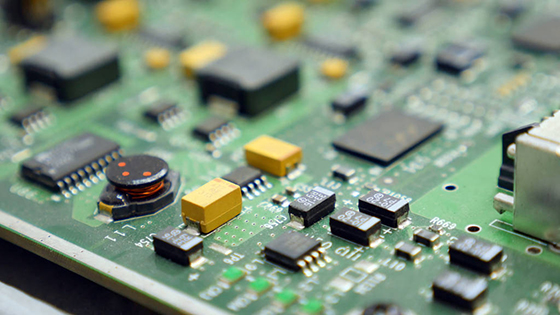

In PCBA factory, flux is an indispensable auxiliary material in the welding process. The quality of the welding effect is not only related to the quality of the welding technolog...

2023/12/13

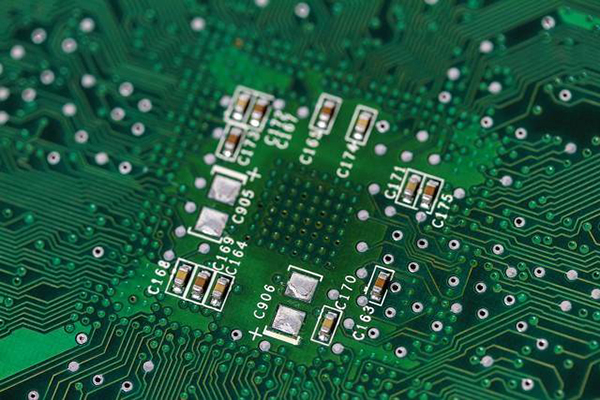

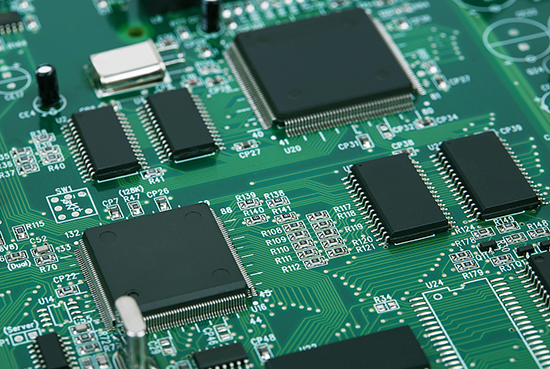

SMT package not only plays the role of placing, fixing, sealing, protecting the chip and enhancing the electrical and thermal performance, but also serves as a “bridge”...

2023/12/08

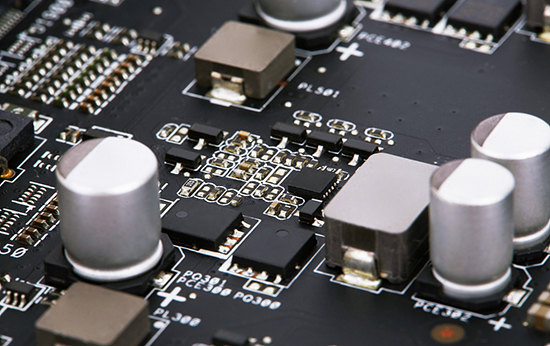

The purpose of the solder mask is to prevent conductor from being stained with tin, prevent short circuits between conductors caused by moisture, chemicals, etc., prevent circuit...

2023/12/05

PCB pulse plating not only significantly improved the quality and in productivity efficient of common multilayer board, but also an indispensable and important method in blind vi...

2023/11/30

In PCB factories, hole metalization usually consists of 8~9 steps of chemical working fluid treatment to complete the entire process. For each technology condition control of eac...

2023/11/29

Whatever it is a 3 layer flexible copper clad laminate or 2 layer flexible copper clad laminate, there are three main manufacturing technologies. Each FCCL manufacturer will...

2023/11/24

FPC is the abbreviation of Flexible Printed Circuit, which is widely popular for its lightness, thinness and flexibility and other characteristics. It uses various materials...

2023/11/22

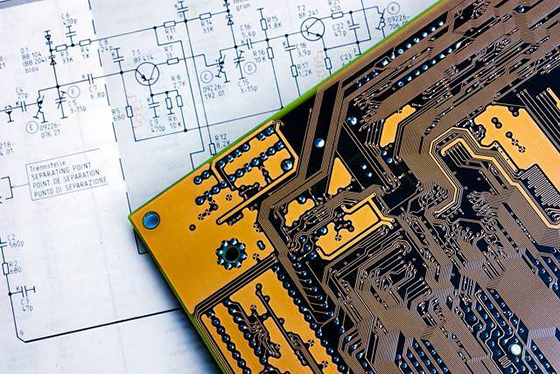

In the PCB manufacturing process, the lamination technology is the most important step. Some quality defects may occur during this process, which will affect the quality of the f...

2023/11/17

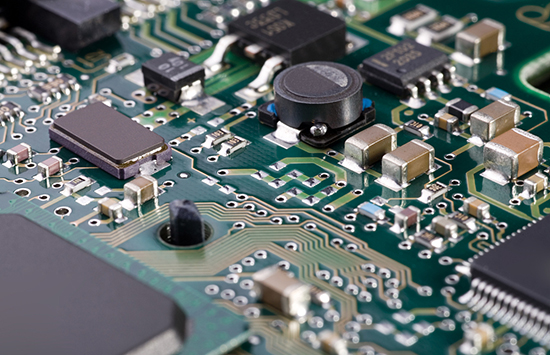

Due to the miniaturization and lightweight of electronic products, the transformation of electronic components from plug-in components to chip components has been promoted,there ...

2023/11/15