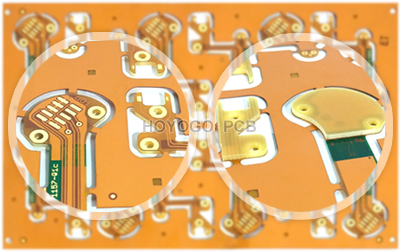

Why should FPC be stiffened? Because the FPC itself is only flexible, and the application scenarios of individual FPC are different, in order to meet the use requirements, it is ...

2022/10/19

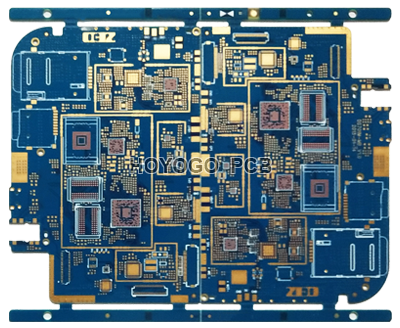

OSP and immersion gold are two common technologies in PCB surface treatment, the purpose of which is to prevent copper surface oxidation and help soldering. So what's the di...

2022/10/14

The PCB break away tab is not part of the PCB, and its existence will consume more boards, thereby increasing the cost of the board, so we need to remove it after the PCBA proces...

2022/10/12

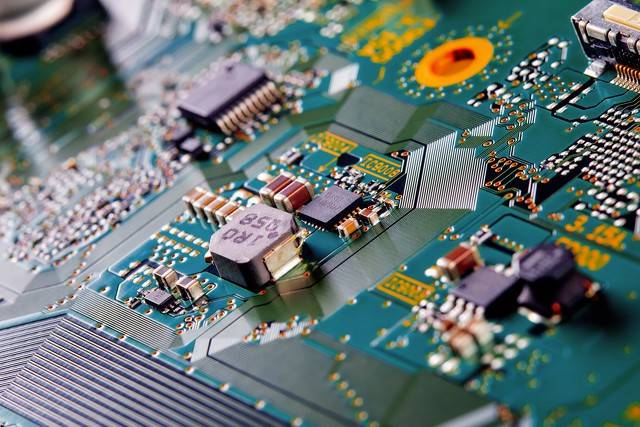

There is a lot of moisture in the air, when the humidity is too high, it will turn into water droplets and fall on the PCB board and electronic components. So what kind of effect...

2022/09/29

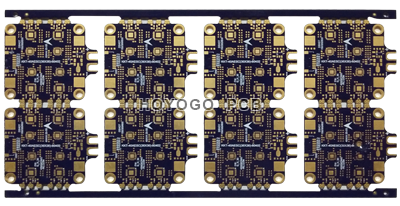

In the PCB processing process, in order to save costs and improve production efficiency, the PCB is usually spliced in the PCB manufacturing link, that is to say, multiple PCB ar...

2022/09/26

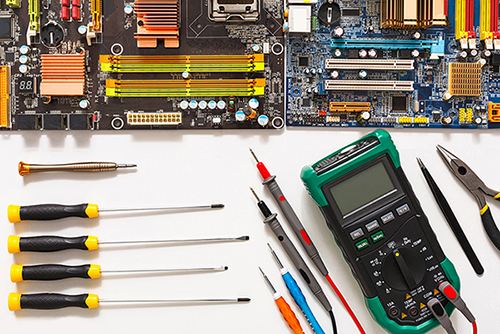

After the PCBA processing is completed, if the product assembly cannot be carried out in time, the PCBA board needs to be properly stored and placed, so how to store it for a lon...

2022/09/21

The copper base PCB is mainly based on copper, and its composition structure are the same as that of the aluminum PCB, which are the copper base lay...

2022/09/16

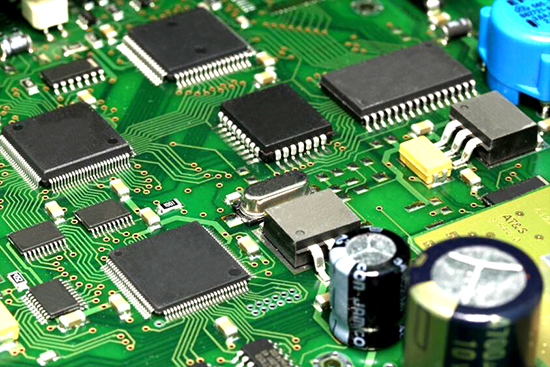

When doing PCBA processing, we occasionally encounter some boards that need to be repaired. Repair is also a very important link. Once errors occur, it may directly lead to the s...

2022/09/09

Both copper base PCB and aluminum PCB belong to PCB IMS boards, which are composed of circuit layers, insulating layers, and metal base layers. It has special magnetic perme...

2022/09/07

Aluminum PCB is a metal substrate with good heat dissipation function. Generally, the single-sided aluminum PCB is composed of three layers, which are the circuit layer, the insu...

2022/09/02